What should I do if I encounter these problems in the PVC blister film process?

by:LINYANG

2022-05-24

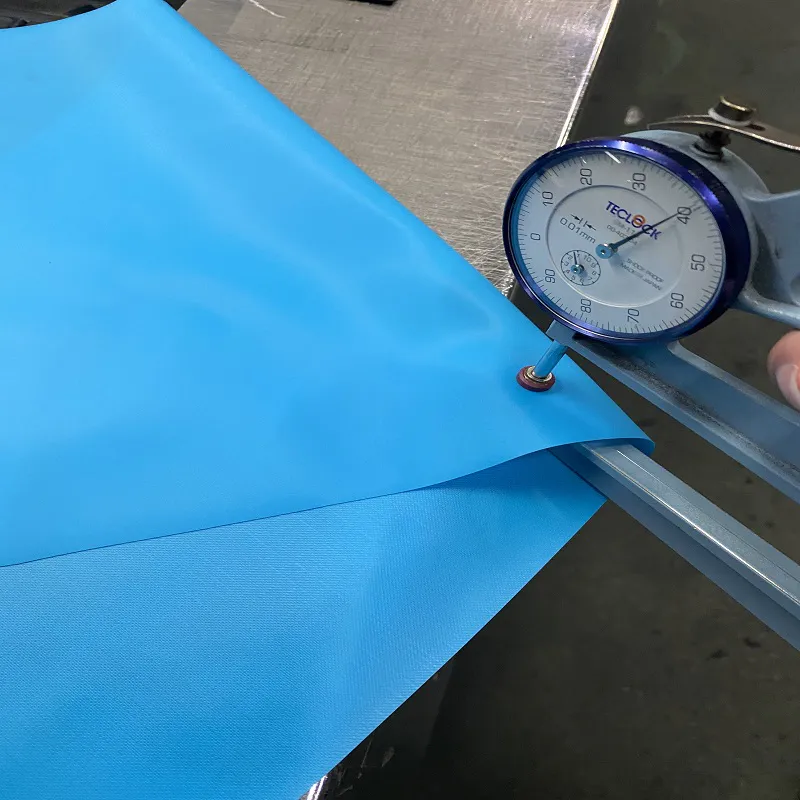

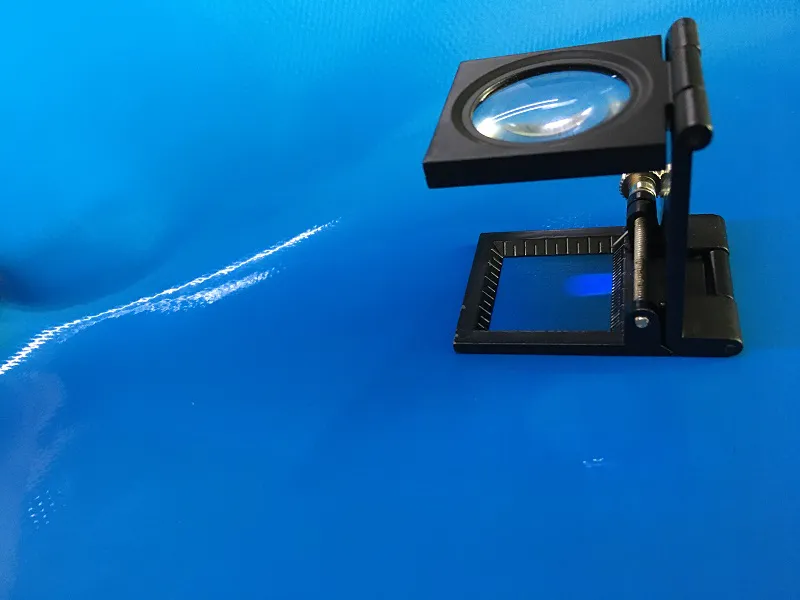

Today, PVC blister film manufacturers introduce some common problems and solutions in the PVC blister process. Phenomenon 1: Analysis of the causes of foaming in the groove: 1. The temperature or pressure does not meet the requirements, resulting in false suction; 2. The amount of glue is not enough, 3. Preheating (softening PVC film) or blister time (molding time) is not enough; 4. After blister molding, if the temperature has not dropped, the pressure will be withdrawn. 5. The heat resistance of the glue itself is not enough. Solution: 1. Increase the temperature or vacuum degree; 2. Increase the amount of glue applied and choose a board with good quality; 3. Increase the preheating or forming time; out of the vacuum. 5. Use with curing agent. Phenomenon 2: Analysis of the causes of local foaming: 1. The glue spraying is uneven, resulting in a small amount of local glue, which reduces the bonding strength; 2. The problem of PVC film, PVC film contains plasticizer, in the case of aging or heating 3. There is a problem with the heating tube in the blister machine, causing uneven temperature. Solution: 1. Try to make the amount of glue sprayed evenly; 2. Use good quality PVC film; 3. Repair the equipment in time. Phenomenon 3: Analysis of the reasons for not being able to absorb or shrinking: 1. During blistering, the side temperature is too low or the vacuum degree is not enough; 2. The temperature resistance of the glue is not enough; 3. After the blister molding, the temperature has not dropped Down the case, just undo the stress. Solution: 1. Increase the temperature or vacuum degree; 2. Use with curing agent; 3. After plastic forming, the temperature is cooled to room temperature or slightly higher, and then the vacuum is withdrawn. Phenomenon 4: Analysis of the causes of pockmarks on the surface of the blistered product: 1. The particle size of the glue is large, and thin PVC film is used, which is easy to produce pockmarks. The characteristics of such pockmarks are uniform dispersion; 2. Use with curing agent When the curing agent is not completely dispersed; 3. The surface of the board is not cleaned, or after the glue is sprayed, there is a lot of dust in the workshop, and the pockmarks are not uniformly dispersed, and the sizes are different; 4. The viscosity of the glue is too large , uneven dispersion; 5. The viscosity of the glue is too small or the solid content is low, causing the board to fluff. Such pits generally appear in the corners of the grooves and appear in blocks. 6. The air pressure of the spray gun is not enough, and the atomization is not good. 7. The glue is not filtered (in this case: a bucket of glue is used at the end, if there is stolen goods or conjunctiva is formed in it, it should be filtered with a filter). Solution: 1. Select glue with small particle size; 2. When preparing curing agent, prolong the stirring time so that the curing agent can be completely dispersed; 3. Clean the surface of the board before spraying glue, and separate the glue spraying workshop; 4. Choose glue with suitable viscosity or high solid content; 5. After the glue is dry, it can be polished with fine sandpaper; 6. Increase the vacuum degree to adjust the atomization effect; 7. When using, filter it with a filter screen. Phenomenon 5: Orange peel occurs locally Cause analysis: 1. Too much glue is sprayed locally; 2. There is oil on the surface of the sheet, which causes the glue to shrink; 3. The curing agent is not completely dispersed, resulting in shrinkage. Solution: 1. Spray the glue evenly in an appropriate amount; 2. Keep the surface of the board clean; 3. Fully stir the curing agent to make it evenly dispersed. Phenomenon 6: Analysis of the causes of wrinkles: (1) The distance between narrow and long workpieces is too small; (2) The edges and corners around the upper surface of the backing plate are not chamfered; (3) The horizontal and vertical distances of the workpiece are not in a straight line, increasing the Resistance to air flow; (4) The set temperature is too high; (5) The time to reach the set pressure is too long. Phenomenon 7: PVC surface whitening Reason analysis: (1) The set temperature is too high; (2) The time to reach the set pressure is too long; (3) The line type is not suitable. Phenomenon 8: Analysis of the reasons why the edge is not fastened: (1) The quality of the glue is not good; (2) The activation temperature of the glue is too high; (3) The temperature of the equipment cannot reach the activation temperature required by the edge of the workpiece; (4) The workpiece pad The board is not suitable; (5) The PVC adhesive performance is not good or there is no adhesive; (6) The adhesive has expired or the storage does not meet the requirements; (7) The glue is leaked or the glue is sprayed improperly. Phenomenon 9: Broken edges and corners This kind of problem generally occurs, the temperature is too high or too low, and the time or length is a problem. Adjusting the temperature and time will improve. When there is a quality problem with the PVC blister film, the process or parameters should be adjusted one by one for the above reasons and recorded. Do not adjust multiple process parameters or processes at the same time, otherwise the real cause of the quality problem will be difficult to identify, and it is also difficult to formulate and Provide an objective basis for adjusting the process standards of the production environment.

If you are sourcing for product development or manufacturing operations, you won't miss ZHONGSHAN LINYANG PLASTIC CO.LTD's list of offer.

Want to learn more about clear pvc film PVC Film? Check out LINYANG PVC Tarpaulin Film.

With so many suggestions and tips on diferent solutions to pvc plastic film issues, it is truly important to know how to find the most appropriate PVC Tarpaulin at economical price.

If you are sourcing for product development or manufacturing operations, you won't miss ZHONGSHAN LINYANG PLASTIC CO.LTD's list of offer.

Want to learn more about clear pvc film PVC Film? Check out LINYANG PVC Tarpaulin Film.

With so many suggestions and tips on diferent solutions to pvc plastic film issues, it is truly important to know how to find the most appropriate PVC Tarpaulin at economical price.

Custom message