Why does PVC blister film generate static electricity?

by:LINYANG

2022-07-01

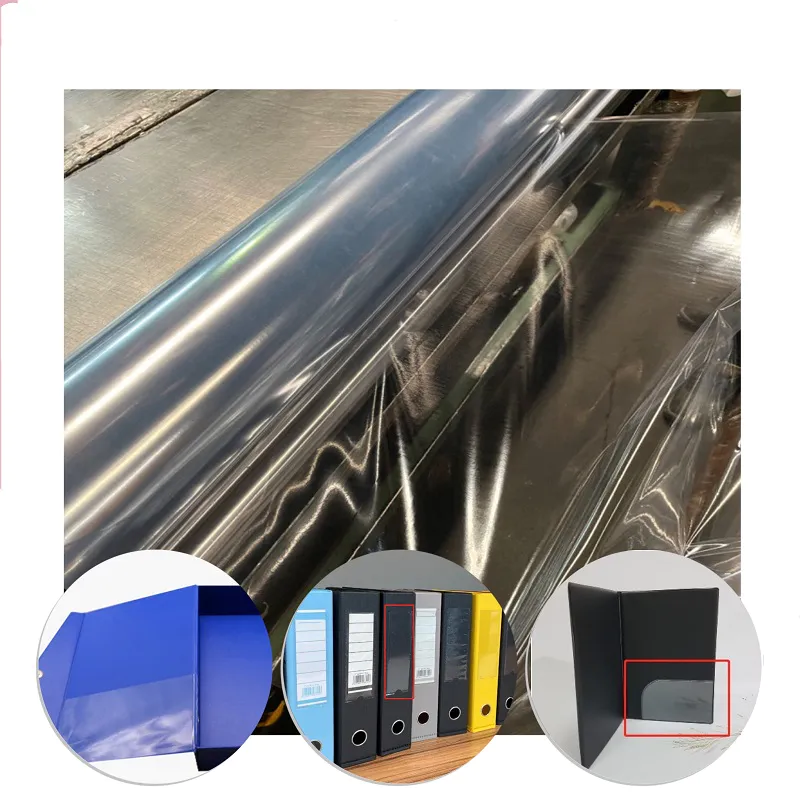

PVC blister film is popular among consumers because of its long-term durability, high quality and low price, and is widely used in furniture such as cabinets. However, many consumers find that PVC blister film sometimes generates some static electricity in daily life, which is very incomprehensible. So today I will give you a detailed analysis to solve your confusion. 1) Static electricity generated during the production of PVC blister film Due to the friction between the pellets, the friction between the melt and the die head, and the friction with the guide roller when the film is wound and wound, the PVC blister film produces static electricity when it leaves the factory. Therefore, in the production process of PVC blister film, an antistatic agent should be added to eliminate this part of static electricity. It should be said that this effect is still very good. Antistatic agents are surfactants in which the molecule contains polar hydrophilic groups and non-polar lipophilic groups. The lipophilic group has a certain compatibility with plastics, and the hydrophilic group can ionize or adsorb moisture in the air, forming a thin conductive layer on the surface of the PVC blister film, which is used to leak electric charges, so as to achieve the purpose of eliminating static electricity. 2) Static electricity generated in the process of printing, compounding, slitting and bag making Due to the friction between the PVC blister film and the guide roller, the friction between the high-speed PVC blister film and the dry air, etc., the PVC blister film generates static electricity. This part of static electricity has the greatest impact on production, and if it cannot be effectively eliminated, it will also have a great impact on post-processing procedures. Generally speaking, it is more effective to use a superconducting electrostatic brush (contact elimination), which is to contact the PVC blister film to pass the generated static electricity through a brush with a low resistance (1m wide resistance less than 1). Ground export to solve this problem. The ion generator can also be used, and the generated ions are blown onto the PVC blister film in the form of wind (non-contact type). However, in actual operation, when the ion gas eliminates the static electricity of the PVC blister film, it will be found that the running PVC blister film will also carry a part of the ions in the air into the winding. 3) Static electricity generated by the finished PVC blister film on the automatic packaging machine The friction between the finished PVC blister film and the equipment guide roller, the PVC blister film itself is not completely eliminated static electricity and other reasons. It causes difficulties in automatic packaging and the required contents are sensitive to static electricity. At this time, the above methods can also be used to eliminate static electricity. The most effective way is to use the superconducting electrostatic brush method to eliminate. Therefore, it is normal for PVC blister film to generate static electricity, especially in relatively dry areas in the north, it will not cause other problems, and you can use it with confidence. Okay, the editor's sharing today is here. If you want to know more about PVC blister film, please click to enter our official website for details.

Custom message