What is the difference between PVC and PVDC film?

PVC (Polyvinyl Chloride) and PVDC (Polyvinylidene Chloride) are two commonly used films in various industries. While both of them have similar chemical properties, they differ significantly in terms of their benefits, applications, and overall performances. In this article, we will explore the differences between PVC and PVDC films, their unique characteristics, and the diverse industries they cater to.

1. Introduction to PVC and PVDC Films

2. Chemical Composition and Manufacturing Process

3. Physical Properties and Barrier Performance

4. Applications and Industries

5. Environmental Considerations

Introduction to PVC and PVDC Films

Both PVC and PVDC films are widely utilized across industries due to their versatility. These films provide an effective barrier against moisture, gases, and chemicals, making them ideal for packaging applications. However, PVC and PVDC have distinct properties that make them suitable for specific purposes.

Chemical Composition and Manufacturing Process

PVC is a synthetic plastic polymer made from the polymerization of vinyl chloride monomers. Its chemical formula is (CH2-CHCl)n, where n represents the degree of polymerization. On the other hand, PVDC is a vinyl polymer that is derived from the polymerization of vinylidene chloride monomers with the chemical formula (CH2-CCI2)n.

The manufacturing processes for PVC and PVDC films involve extrusion, where the respective polymers are melted and then shaped into thin sheets. PVC films can be produced with the addition of various plasticizers and stabilizers to improve flexibility and durability. PVDC, however, does not require plasticizers due to its inherent flexibility and stability.

Physical Properties and Barrier Performance

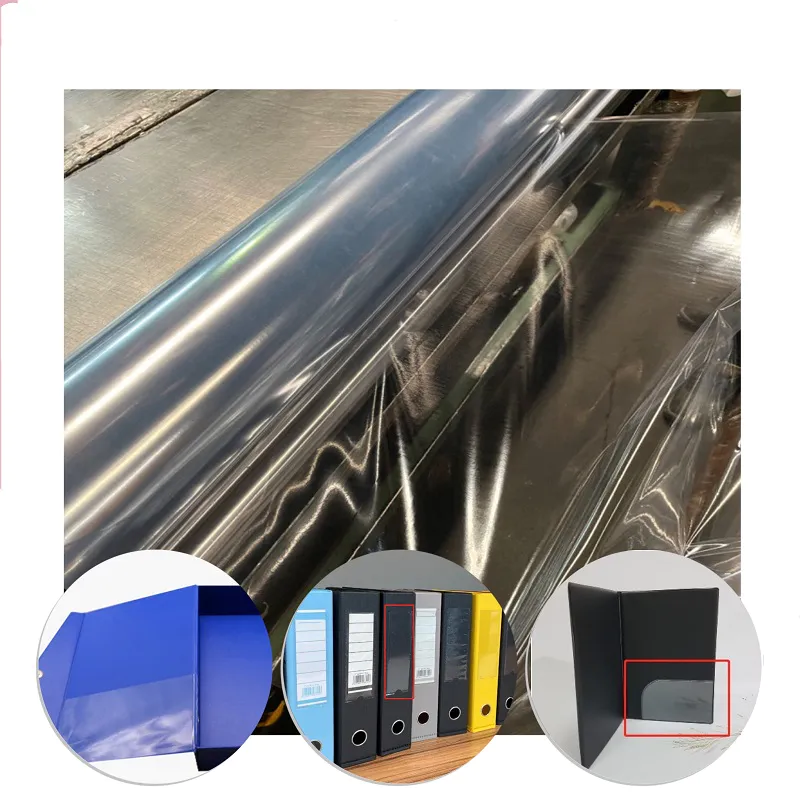

PVC films possess good transparency, allowing for easy visibility of the contents within. They offer excellent flexibility, making them suitable for applications that involve bending or shaping the material. Additionally, PVC films have good printability, allowing for vibrant graphics and product labeling.

PVDC films, on the other hand, have exceptional barrier properties. They provide excellent resistance to moisture vapor transmission, ensuring that the packaged products remain protected against humidity, odors, and gases. PVDC films also exhibit outstanding oxygen barrier properties, making them ideal for products that are sensitive to oxidation or require extended shelf life.

Applications and Industries

PVC films find widespread use in various industries such as food packaging, pharmaceuticals, consumer goods, and construction materials. In the food industry, PVC films are commonly employed for wrapping cheese, meat, and other perishable items. They are also utilized in the production of labels, tapes, inflatable toys, and medical products.

PVDC films are predominantly used in the pharmaceutical and healthcare industries. Due to their excellent barrier properties, PVDC films are utilized for blister packaging of tablets, capsules, and other medications. They ensure the preservation of the product's efficacy, protect it from external contaminants, and provide tamper-evident packaging solutions.

Environmental Considerations

When it comes to environmental impact, PVC films have been subject to scrutiny due to the potential release of chlorine gas during incineration. This gas emission can contribute to air pollution and negatively impact human health. However, PVC films can be recycled through specialized recycling processes, which mitigates their environmental impact to some extent.

In contrast, PVDC films are considered more environmentally friendly due to their lack of chlorine content. PVDC can be recycled or incinerated without producing harmful emissions. Moreover, advancements in PVDC film production have led to the emergence of bio-based PVDC films, reducing their reliance on petroleum-based sources and further improving their sustainability.

Conclusion

In summary, PVC and PVDC films are widely used in diverse industries, thanks to their unique characteristics and performance benefits. While PVC films offer good flexibility, transparency, and printability, PVDC films excel in providing exceptional barrier properties against moisture and gases. Understanding the differences between these two films allows businesses to choose the most suitable option for their specific applications, taking into consideration factors such as performance requirements and environmental impact.

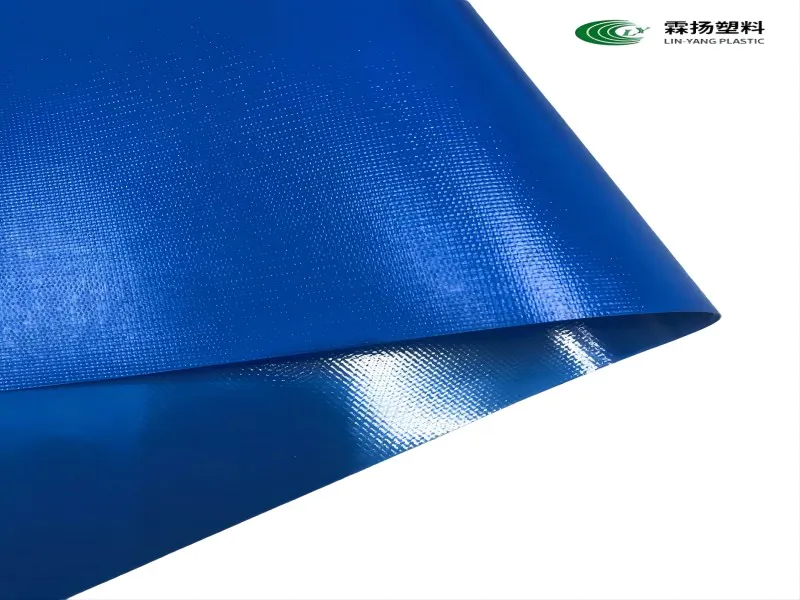

ZHONGSHAN LINYANG PLASTIC CO.LTD is always trying to better understand the PVC Tarpaulin of innovation, so we can help companies lead the industries.

ZHONGSHAN LINYANG PLASTIC CO.LTD serves a wide variety of professional markets and industries across the globe. Contact us at LINYANG PVC Tarpaulin Film to find the you have always dreamt of.

PVC Film has its grasp on oversees market and has a very good repute. Our products are available at very competitive prices.

We believe in keeping the customers happy and providing them with PVC Tarpaulin at a very competent price.