What is the difference between PVC and PE film?

What is the Difference Between PVC and PE Film?

Introduction:

Plastic films are versatile materials used in various industries for packaging, construction, agriculture, and many other applications. Two commonly used types of plastic films are Polyvinyl Chloride (PVC) and Polyethylene (PE) films. While both are popular choices, they have distinct differences in terms of composition, properties, and applications. This article explores the dissimilarities between PVC and PE films, shedding light on their individual characteristics and uses.

Composition:

1. PVC Film:

Polyvinyl Chloride, commonly known as PVC, is a synthetic thermoplastic polymer. It is made up of repeating vinyl chloride monomer units that undergo polymerization. PVC is composed of 57% chlorine and 43% carbon, making it an efficient and stable plastic material. The use of chlorine in its composition allows for diverse variations in PVC properties.

2. PE Film:

Polyethylene, often abbreviated as PE, is another thermoplastic polymer. It is created from the polymerization of ethylene monomer units. PE consists purely of carbon and hydrogen atoms, providing it with excellent chemical resistance and electrical insulation properties. The arrangement of ethylene monomers determines the density and overall characteristics of PE films.

Properties:

1. PVC Film:

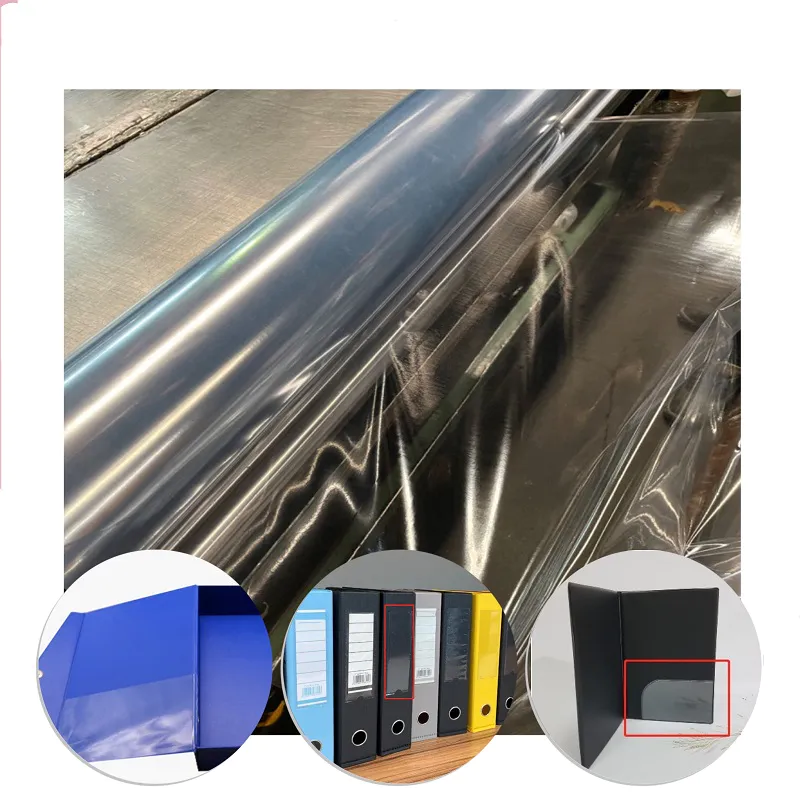

PVC films possess several unique properties that make them suitable for numerous applications. Firstly, PVC films are known for their excellent strength and durability. They have high tensile strength and can withstand heavy loads, making them ideal for packaging and industrial applications. Additionally, PVC films are resistant to moisture, chemicals, and UV radiation, ensuring the integrity of the packaged goods. They also exhibit good dimensional stability, which makes them an excellent choice for heat sealing processes.

2. PE Film:

PE films come in different densities, namely Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), and High-Density Polyethylene (HDPE). These densities impart distinct properties to PE films. LDPE films are flexible, transparent, and have excellent impact resistance. LLDPE films have higher tensile strength and puncture resistance, making them suitable for heavy-duty packaging. HDPE films are rigid, have exceptional tensile strength, and are often used for construction purposes.

Applications:

1. PVC Film:

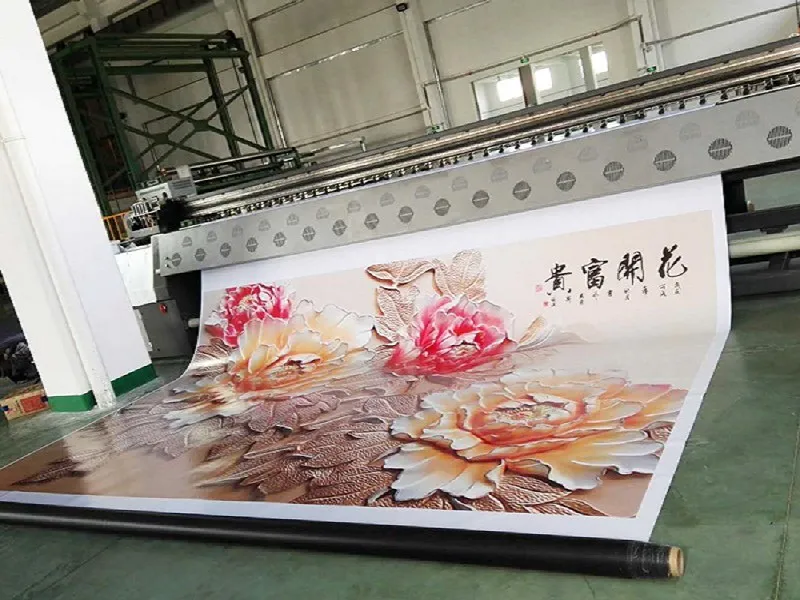

Due to their unique properties, PVC films find applications in a wide array of industries. They are extensively used for packaging food, pharmaceuticals, and consumer goods due to their excellent barrier properties. PVC films are also commonly employed for shrink wrapping, providing a protective and tamper-evident covering. Additionally, they find utility in the construction industry for insulation purposes, electrical cable coating, and window frames.

2. PE Film:

PE films, with their versatile characteristics, have diverse applications across industries. LDPE films are often used as food wraps, bags, and agricultural covers. Their flexibility and transparency make them suitable for these purposes. LLDPE films are used for heavy-duty packaging, such as shipping sacks and stretch films. HDPE films are popularly utilized for geomembranes, pond liners, and garbage bags due to their strength and durability.

Environmental Considerations:

1. PVC Film:

PVC has been a subject of environmental debates due to the presence of chlorine in its composition. When burned, PVC releases dioxins that are harmful to the environment. Moreover, PVC films are not always recyclable and can take a long time to degrade in landfills. However, advancements in PVC manufacturing have led to the development of more environmentally friendly options, such as phthalate-free PVC films.

2. PE Film:

PE films have a better environmental profile compared to PVC films. They are generally considered more eco-friendly and have lower carbon footprints. PE films can be recycled effectively, reducing waste and conserving resources. However, the recycling process for PE films can be complex due to different densities, making it essential to separate them accordingly.

Conclusion:

In conclusion, PVC and PE films have distinct differences that make them suitable for diverse applications. PVC films exhibit excellent strength, chemical resistance, and dimensional stability, finding applications in packaging, construction, and electrical industries. On the other hand, PE films come in various densities, each offering unique characteristics such as flexibility, tensile strength, and puncture resistance. The choice between PVC and PE films depends on the specific requirements of the application, emphasizing the importance of understanding these differences to make informed decisions.

LINYANG is the unique producer of PVC Film and related products.

Are you interested in buying ? We also have all kinds of in offer. Visit LINYANG PVC Tarpaulin Film to know more and order, we have them at pocket friendly prices.

Among improvements to PVC Tarpaulin, nearly half of consumers considered quality and service as the most important change a business could make in its supply chain.

ZHONGSHAN LINYANG PLASTIC CO.LTD deems PVC Film as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.