LINYANG best pvc film manufacturer

Width Range:

20~82.5inch

Thickness Range:

0.08mm~1mm

Softness Range:

20PHR to 40PHR

Embossing:

over 30 kinds of embossing patterns

Color:

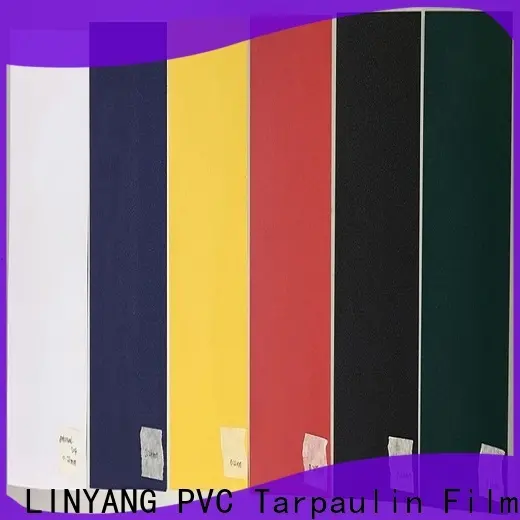

Per pantone colors or customer-supplied samples

Company Advantages

1. The manufacture of LINYANG pvc film manufacturers complies with regulatory standards. They mainly are GS mark, DIN, EN, RAL GZ 430, NEN, NF, BS, or ANSI/BIFMA, etc. Why do you need a high-quality PVC film? Lin-Yang Plastic will tell you the answer

2. This product brings sustainability, aesthetic beauty, and long-term cost savings. It is a unique method to transform a utilitarian structure into an ever-changing work of art. Durable and high quality PVC tarpaulin are available in all colors. Contact Lin-Yang Plastic now

3. The product guarantees good strength for the item. It also offers endurance and has proven to last through years of wear and tear. Say hi from Lin-Yang high-end PVC film

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-4]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-5]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-6]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-7]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-8]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-9]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-10]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-11]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-12]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-13]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-14]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-15]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-16]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-17]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-18]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-19]()

![LIN-YANG-Best High Tensile Strength, Weatherability, Waterproof, Anti-fouling-20]()

Company Features

1. LINYANG enjoys good word-of-mouth in the world. The factory implements a strict quality control system to guide the whole production process. This system has helped increase the whole productivity and regulate the operation, which eventually contributes to improving product quality.

2. We have invested in a series of advanced manufacturing facilities. These machines are equipped with the latest production technologies, which can ensure that we can manufacture our products at the highest level.

3. With a production certificate, we are authorized to manufacture and market products freely. Besides, this certificate supports the company entering into the market. Our company are always following service tenet: pvc film manufacturers. Get info!

1. The manufacture of LINYANG pvc film manufacturers complies with regulatory standards. They mainly are GS mark, DIN, EN, RAL GZ 430, NEN, NF, BS, or ANSI/BIFMA, etc. Why do you need a high-quality PVC film? Lin-Yang Plastic will tell you the answer

2. This product brings sustainability, aesthetic beauty, and long-term cost savings. It is a unique method to transform a utilitarian structure into an ever-changing work of art. Durable and high quality PVC tarpaulin are available in all colors. Contact Lin-Yang Plastic now

3. The product guarantees good strength for the item. It also offers endurance and has proven to last through years of wear and tear. Say hi from Lin-Yang high-end PVC film

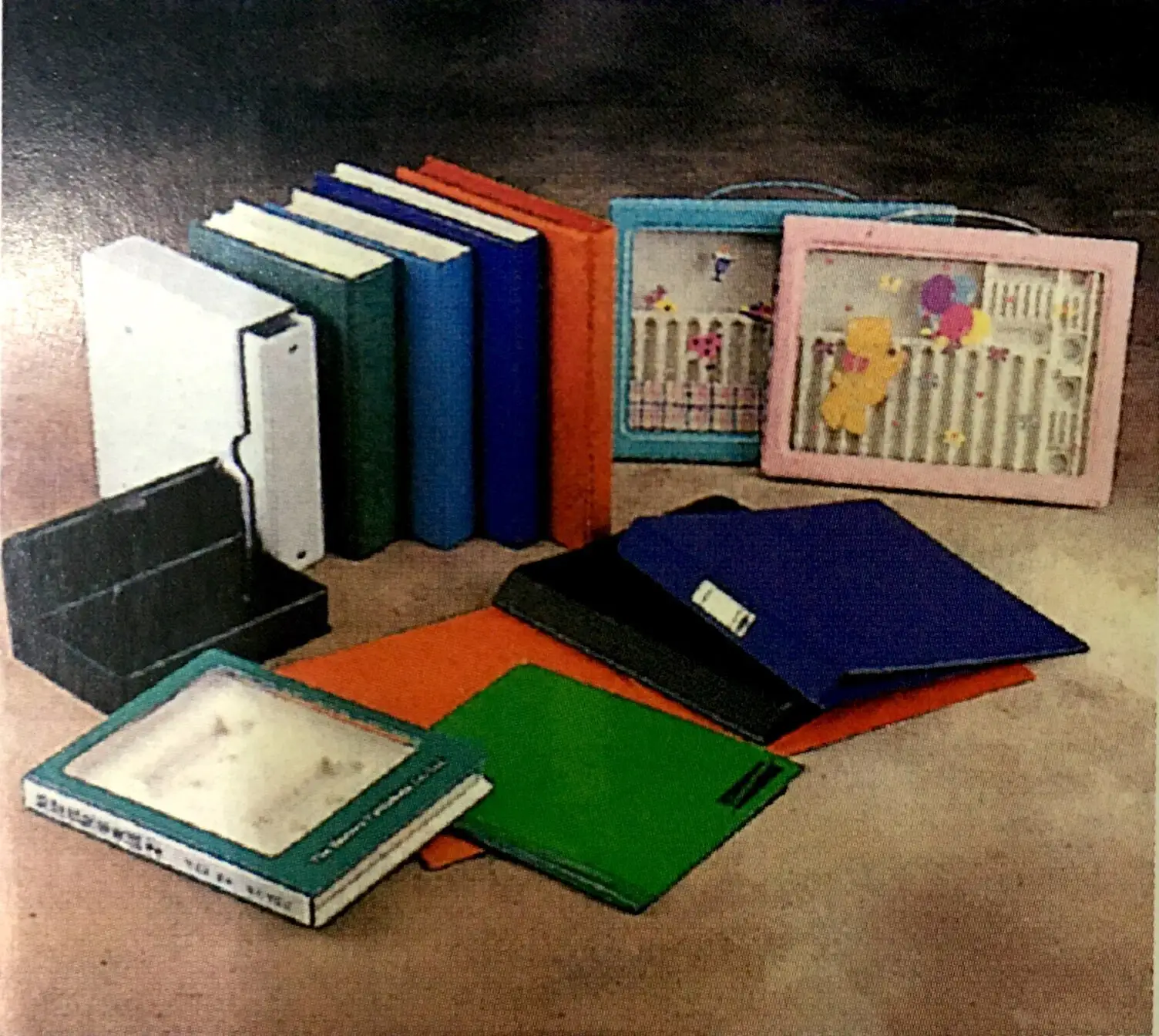

PVC film is the very suitable material for making stationery because there are many kinds of embossing on pvc film , it can make stationery very beautiful and nice.

Also pvc film has a variety color , plus transparent and translucent film , it can make a lot of different kind of stationery.

With different hardness / softness , PVC fiim is good for making different kind of product based on customer's requirement.

Statonery including file pocket , document pouch ,stationery holder, ring binder and so on.

Generally , The softness of pvc film for stationery application is from 20 PHR to 36 PHR, it belongs to semi-rigid PVC film.

Detailed product parameters

bg

| DESCRIPTION | TECHNICAL REQUIREMENTS | Stationery PVC Film |

| Color | Per pantone colors or customer-supplied samples | |

| Width Range | 20 ~ 82.5 inch | |

| Thickness Range | 0.08mm~1mm | |

| Softness Range | 20PHR to 40PHR (70PHR and above will be charged additionally) | |

| Embossing | over 30 kinds of embossing patterns | |

Special Formula The following standards can be fulfilled with our special formula, and will be charged additionally. | EN-71 part I to part VIII | |

| ASTM963 / D3421-75 /D1790 | ||

| RoHS test | ||

| PAHs test | ||

| DEHP<3%, DEHP<0.1% | ||

| Japan Toy Safety Standard | ||

| Flammability Test BS5852 | ||

| 3P <1000PPM | BBP, DBP, DEHP | |

| 6P <1000PPM | Phthalate-free <0.01% (DINP, DNOP, DEHP, DIDP, BBP, DBP) | |

| 15P <1000PPM | Phthalate-free <0.01% (DBP,DMP,DEP,DEHP,DINP,BBP,DPP,DNOP,DNP,DIDP,DCHP,DPRP,DHP,DIBP,DIOP) | |

| — 30 > —10(Degrees Celsius) | Freeze test | |

| 100 ~ 30000(HRS) | Anti-ultraviolet (UV) rays | |

| Anti-mildew | ||

| Fire retardant | ||

| < 10PPM | Consumption of potassium permanganate | |

| < 5PPM | Phenol | |

| < 1PPM | Vinyl-chloride | |

| Free of AZO dye compound (amines-free) | ||

| Free of tin-organic | ||

| Free of nonylphenol |

Product application

bg

Features

bg

The reason why PVC calender is so widely used is that it has the following characteristics:

part.1

High tensile strength

The tensile strength of PVC film is up to 29MPa. PE film and EVA film were damaged in all the dust storms in northwest China, except PVC film

part.2

Good insulation performance

As a covering material for agricultural greenhouses, glass has the best thermal insulation performance, followed by PVC calender film (with strong infrared absorption capacity) and PE film. In addition, at night, the thermal insulation performance of PVC film is not different from that of glass, which is very beneficial to the growth of crops.

part.3

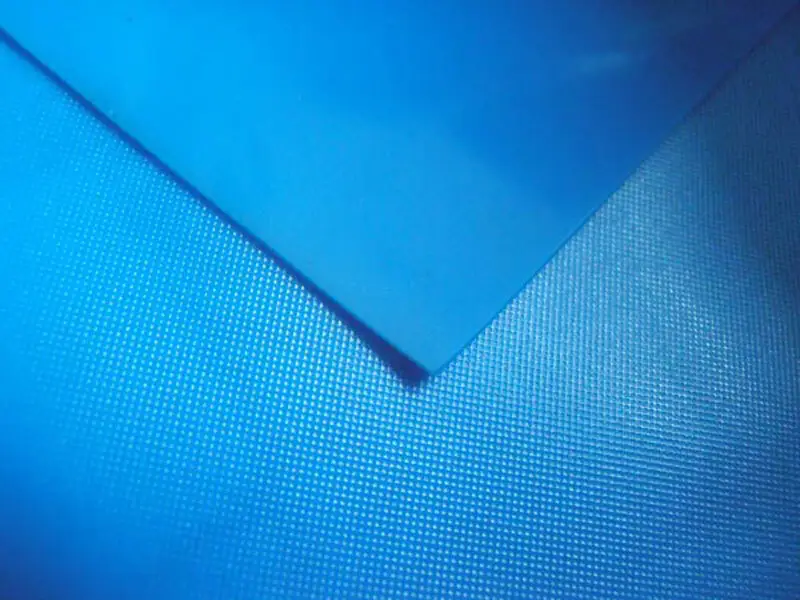

Good transparency

The PVC calendering film is extruded by the mirror roller in the process of forming. The surface is highly polished, and the condensation of water droplets is less, so the transmittance is higher, which is beneficial to the photosynthesis of crops

part.4

Uniform thickness

Since the roll tube of PVC calender film is in the shape of medium drum and the middle roll crosses, the lower roll has prestrain and the roll surface has been finely ground, so the thickness accuracy is high

part.5

Good adhesion performance

According to the need of use, PVC calender film can be used high frequency welding, thermal bonding and adhesive bonding methods, easy to use. In addition, according to the different USES of PVC film, the production formula and technological conditions can be changed to meet the requirements

Operation process

bg

calendaring

laminating

Certifications

bg

EN71-3-1

EN71-3-2

EN71-3-3

EN71-3-4

REACH181-2018

REACH181-2018-2

Company Features

1. LINYANG enjoys good word-of-mouth in the world. The factory implements a strict quality control system to guide the whole production process. This system has helped increase the whole productivity and regulate the operation, which eventually contributes to improving product quality.

2. We have invested in a series of advanced manufacturing facilities. These machines are equipped with the latest production technologies, which can ensure that we can manufacture our products at the highest level.

3. With a production certificate, we are authorized to manufacture and market products freely. Besides, this certificate supports the company entering into the market. Our company are always following service tenet: pvc film manufacturers. Get info!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data