Quality color opaque pvc film quality assurance

Width Range:

20 ~ 260inch

Thickness Range:

0.06mm to 1.0mm

Softness Range:

18PHR to 78PHR (70PHR and above will be charged additionally)

Feature:

Good abrasion resistance, high transparency, eco-friendly and stable color

Embossing:

over 30 kinds of embossing patterns

Color:

Per pantone colors or customer-supplied samples

PVC calendaring film is made by calendaring process. Calendaring is the process of making the heated PVC plastic through the space between one or more horizontal rollers rotating in the opposite direction, so that the material can withstand extrusion and extension, and become a thin product with certain thickness, width and smooth surface. Polyvinyl chloride rolling film occupies an important position in plastic shed film. In addition, it is widely used in salt field tarpaulin cover, industrial packaging, electrical insulation, inflatable film products, lamp box advertising, engineering waterproof, daily necessities packaging and other aspects.

Detailed product parameters

bg

| DESCRIPTION | TECHNICAL REQUIREMENTS | Normal PVC film |

| Color | Per pantone colors or customer-supplied samples | |

| Width Range(inch) | Normal calendaring production line | 20 ~ 80inch |

| Thickness Range(mm) | 0.06mm to 1.00mm (max 1.50mm per embossing pattern 666) | |

| Softness Range(phr) | 18PHR to 78PHR (70PHR and above will be charged additionally) | |

| Embossing | over 30 kinds of embossing patterns | |

| Width Range(inch) | Large calendaring production line | 40 ~ 260inch |

| Thickness Range(mm) | 0.12mm to 0.5mm | |

| Softness Range(phr) | 18PHR to 78PHR (70PHR and above will be charged additionally) | |

| Embossing | Three patterns currently : 001 / 002 / 900 | |

Special Formula The following standards can be fulfilled with our special formula, and will be charged additionally. | EN-71 part I to part VIII | |

| ASTM963 / D3421-75 /D1790 | ||

| RoHS test | ||

| PAHs test | ||

| DEHP<3%, DEHP<0.1% | ||

| Japan Toy Safety Standard | ||

| Flammability Test BS5852 | ||

| 3P <1000PPM | BBP, DBP, DEHP | |

| 6P <1000PPM | Phthalate-free <0.01% (DINP, DNOP, DEHP, DIDP, BBP, DBP) | |

| 15P <1000PPM | Phthalate-free <0.01% (DBP,DMP,DEP,DEHP,DINP,BBP,DPP,DNOP,DNP,DIDP,DCHP,DPRP,DHP,DIBP,DIOP) | |

| — 30 > —10 | Freeze test | |

| 100 ~ 30000 | Anti-ultraviolet (UV) rays | |

| Anti-mildew | ||

| Fire retardant | ||

| < 10PPM | Consumption of potassium permanganate | |

| < 5PPM | Phenol | |

| < 1PPM | Vinyl-chloride | |

| Free of AZO dye compound (amines-free) | ||

| Free of tin-organic | ||

| Free of nonylphenol |

Product application

bg

Features

bg

The reason why PVC calender is so widely used is that it has the following characteristics:

part.1

High tensile strength

The tensile strength of PVC film is up to 29MPa. PE film and EVA film

were damaged in all the dust storms in northwest China, except PVC film

part.2

Good insulation performance

As a covering material for agricultural greenhouses, glass has the best

thermal insulation performance, followed by PVC calender film (with

strong infrared absorption capacity) and PE film. In addition, at night,

the thermal insulation performance of PVC film is not different from

that of glass, which is very beneficial to the growth of crops.

part.3

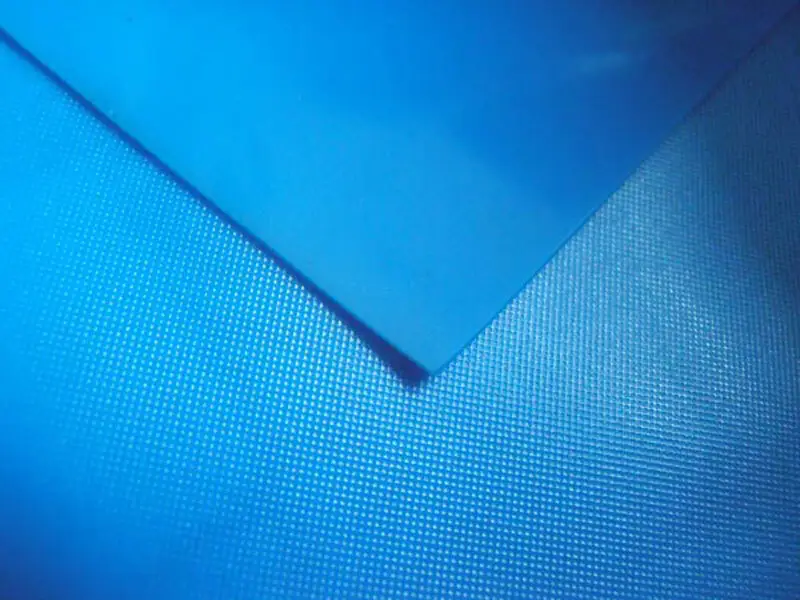

Good transparency

The PVC calendering film is extruded by the mirror roller in the process

of forming. The surface is highly polished, and the condensation of

water droplets is less, so the transmittance is higher, which is

beneficial to the photosynthesis of crops

part.4

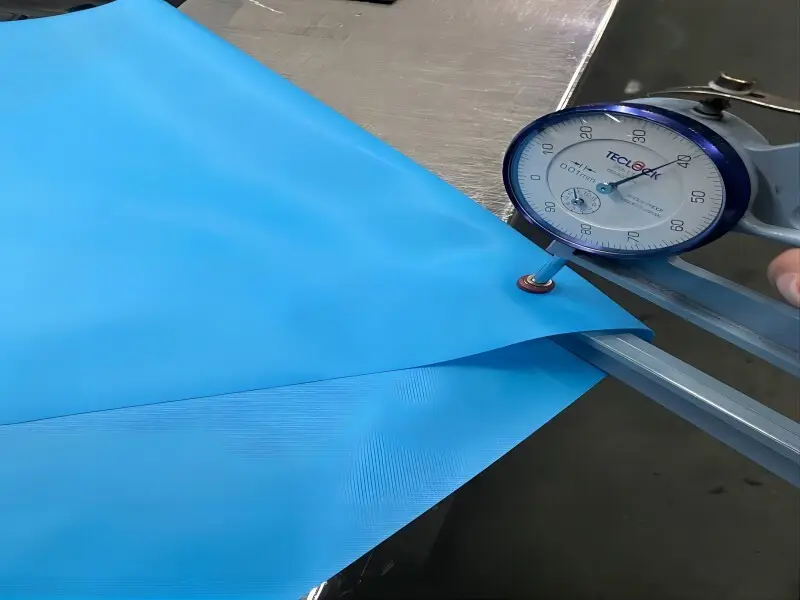

Uniform thickness

Since the roll tube of PVC calender film is in the shape of medium drum

and the middle roll crosses, the lower roll has prestrain and the roll

surface has been finely ground, so the thickness accuracy is high

part.5

Good adhesion performance

According to the need of use, PVC calender film can be used high

frequency welding, thermal bonding and adhesive bonding methods, easy to

use.

In addition, according to the different USES of PVC film, the production

formula and technological conditions can be changed to meet the

requirements

Operation process

bg

calendaring

laminating

Certifications

bg

EN71-3-1

EN71-3-2

EN71-3-3

EN71-3-4

REACH181-2018

REACH181-2018-2

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data