PVC blister film manufacturers introduce the blister process

by:LINYANG

2022-07-05

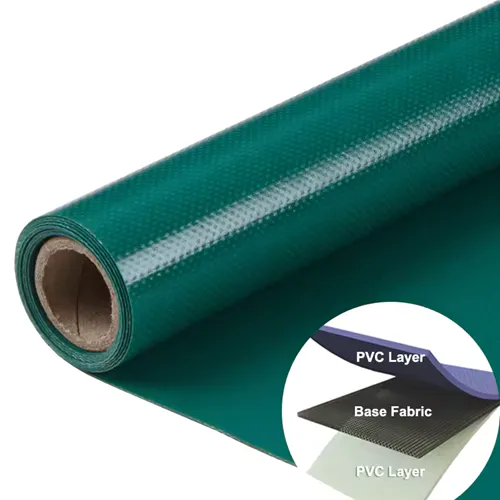

We know what PVC blister film is, but do you know the blister process for making blister film? Blister is a plastic processing technology. The surface of the mold is formed after cooling. It is widely used in plastic packaging, lighting, advertising, decoration and other industries. Blister packaging products mainly include: blister, tray, blister box. Packaging equipment mainly includes: blister forming machine. Punching machine. Sealing machine. High frequency machine. Folding machine. Packaging products formed by packaging can be divided into: plug-in. Folding blister, etc. The transparent plastic hard sheet is made into a specific convex transparent plastic by the blister process, which is covered on the surface of the product to protect and beautify the product, and the surface of the ordinary plastic hard sheet is glued with a layer Solute material, so that the surface of the tray has a kind of solute feel, which is used to improve the grade of packaging products. The plastic tray using special process modified material, the resistance value of the material surface is less than 10 ohms for 11 times. It is mainly used for electronic .The electrostatic tray for IT products. For the molds used in the plastic production, the lowest cost is the plaster mold, the second is the electroplated copper mold, and the most expensive is the aluminum mold. , to form a blister product. The blister we often talk about uses a blister molding machine to adsorb the thermally softened plastic hard sheet on the surface of the mold, and after cooling, it forms a plastic with a concave and convex shape. For plastic products, after punching, the large sheets are divided into individual products with a knife die. Folding: There is a kind of plug-in packaging in blister packaging, and the three sides of the blister need to be folded to the back with a folding machine. In the next packaging process, the paper card is inserted into the folded edge to form a card package. Heat sealing: It is a blister packaging process. The paper card and the blister coated with blister oil are also combined with a sealing machine. , form a blister package, High frequency sealing: It is a blister packaging process that uses a high frequency machine to generate ultrasonic waves to bond the blister and the blister together to form a double blister package. The difference from high frequency sealing is that ultrasonic It can not only seal PVC, PET, PETG materials, but also PET materials, and has electromagnetic damage to the packaged products, especially suitable for the packaging of electronic products: the disadvantage is that the ultrasonic edge sealing can only be spaced in dots, and generally It only seals one side at a time. In addition to the blister process introduced by the PVC blister film manufacturer above, you can do some understanding. In fact, we use the blister process in many places now, such as the production of food packaging bags. The blister film used on furniture such as cabinets and wardrobes will all use the blister process. The above is the whole content of today. You are welcome to continue to pay attention to our official website.

Custom message